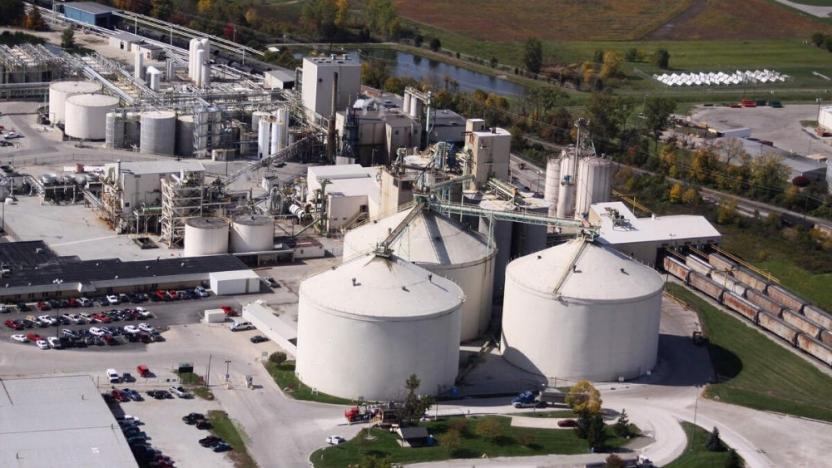

Delivering Advanced Engineering Solutions: The 22-Tank Farm Project

The customer, based in Turkey, is an industry leader providing safe, innovative, and efficient bulk liquid storage solutions. Their comprehensive services cater to all types of liquid products, including chemical, petroleum, and vegetable oils. They are committed to delivering top-quality services while prioritizing safety, reliability, and sustainability.

In 2018, Gizil had the honor of collaborating with the customer, a renowned company in the bulk liquid storage sector. The project was focused on the development of a large-scale tank farm consisting of 22 storage tanks. This project was executed with meticulous planning and execution, adhering to the highest standards of quality and safety. As the engineering contractor for this large-scale project, Gizil was entrusted with managing all engineering aspects. Leveraging our expertise in executing multi-disciplinary projects, we delivered comprehensive engineering deliverables across all disciplines involved.

The project presented unique challenges, requiring precise engineering and robust project management skills. The complexity of coordinating multiple disciplines, coupled with the stringent safety standards of bulk liquid storage facilities, made this a demanding task. Furthermore, designing a storage system for a diverse range of liquids, each with different properties and storage requirements, added another layer of complexity.

At Gizil, we believe in tackling challenges head-on. This project was approached with a three-pronged strategy - meticulous planning, innovative engineering, and stringent quality control. The planning phase involved a comprehensive study of customer's requirements, the nature of the liquids to be stored, and the site conditions. Detailed schedules were drawn up, ensuring that all stages of the project were well-coordinated. Our team utilized cutting-edge engineering tools and techniques to design and plan the construction of the tank farm. From the structural designs of the tanks to the layout of the entire facility, all aspects were engineered to ensure optimal functionality and safety. Adhering to the high safety and quality standards was paramount. Regular inspections and audits were carried out throughout the project lifecycle, ensuring all work was in line with the project specifications and safety guidelines.

Our Achievements:

- Successful completion of the project within the stipulated timeframe and budget.

- Overcame engineering challenges through innovative solutions.

- Adherence to stringent safety and quality standards, resulting in an accident-free project lifecycle.

- Received positive feedback from the client for our professional management and high-quality workmanship.

The project significantly bolstered customer's storage capacity, helping the company cater to a larger market. The newly constructed tank farm adhered to the highest safety standards, ensuring reliable and safe storage of various liquid products. The project served as a testament to customer’s commitment to operational excellence and contributed positively to their growth trajectory.