GIZIL assists process industries and EPC companies produce a revised set of as-built drawings for construction by properly charting the dimensions and locations of work-in-progress and finished jobs. We do not suggest verifying P&IDs with the 3D model or laser scanning data according to our experience so far.

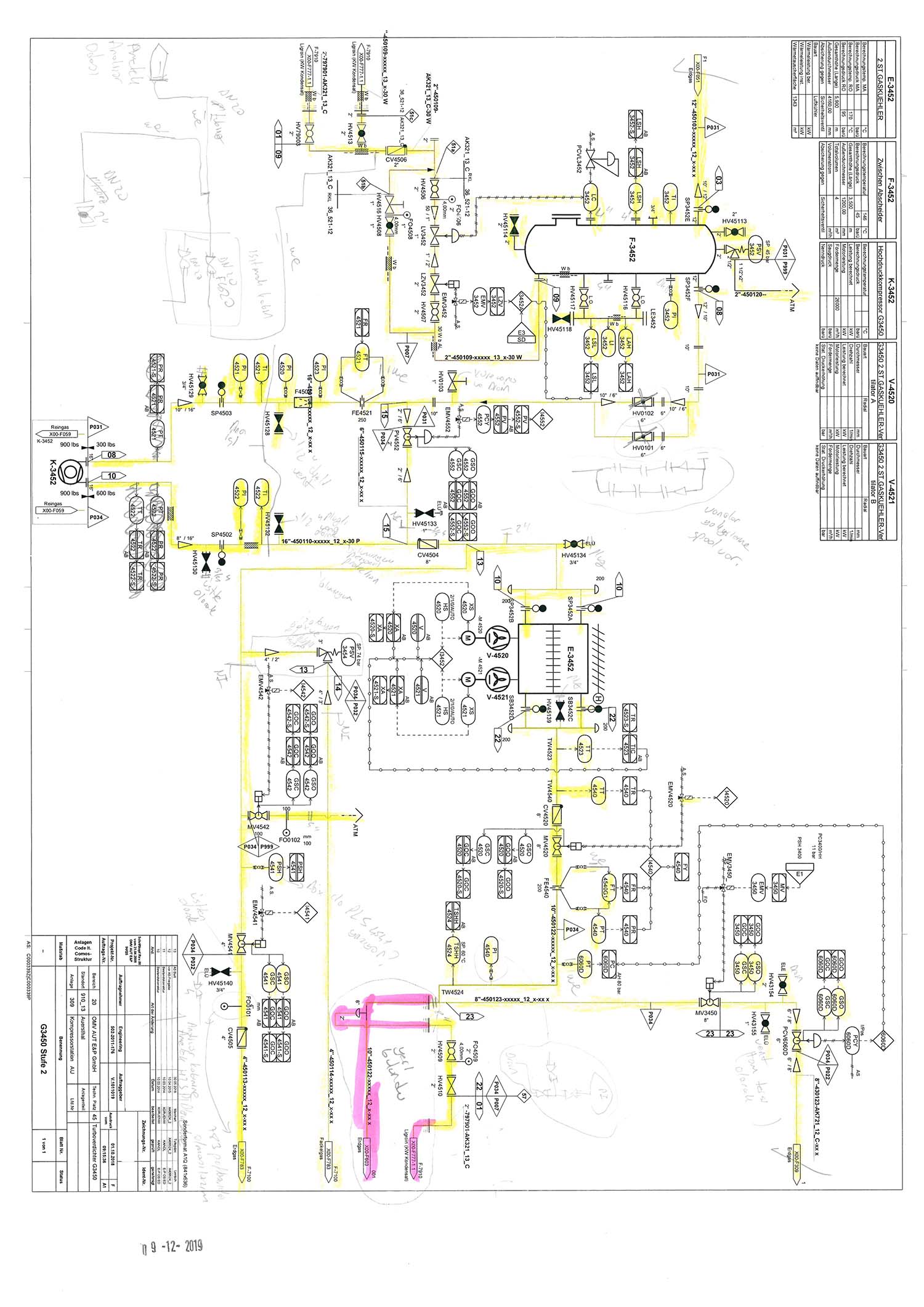

A team of qualified engineers is mobilized for field walk down, verification, and red lining at the site. Since as-built P&ID and piping specifications are the prerequisites for 3D modeling. Thus, we prefer to mobilize a field engineer team for P&ID as a built-in parallel to the laser scanning team. Otherwise, there are disadvantages of P&ID verification thru 3d model or laser scan data which result in more time and money, such as:

- Invisible parts on point cloud data,

- Difficulties in measuring pipe size,

- Difficulties to clarify equipment/ instrument type,

- Uncertainty about insulation, etc.

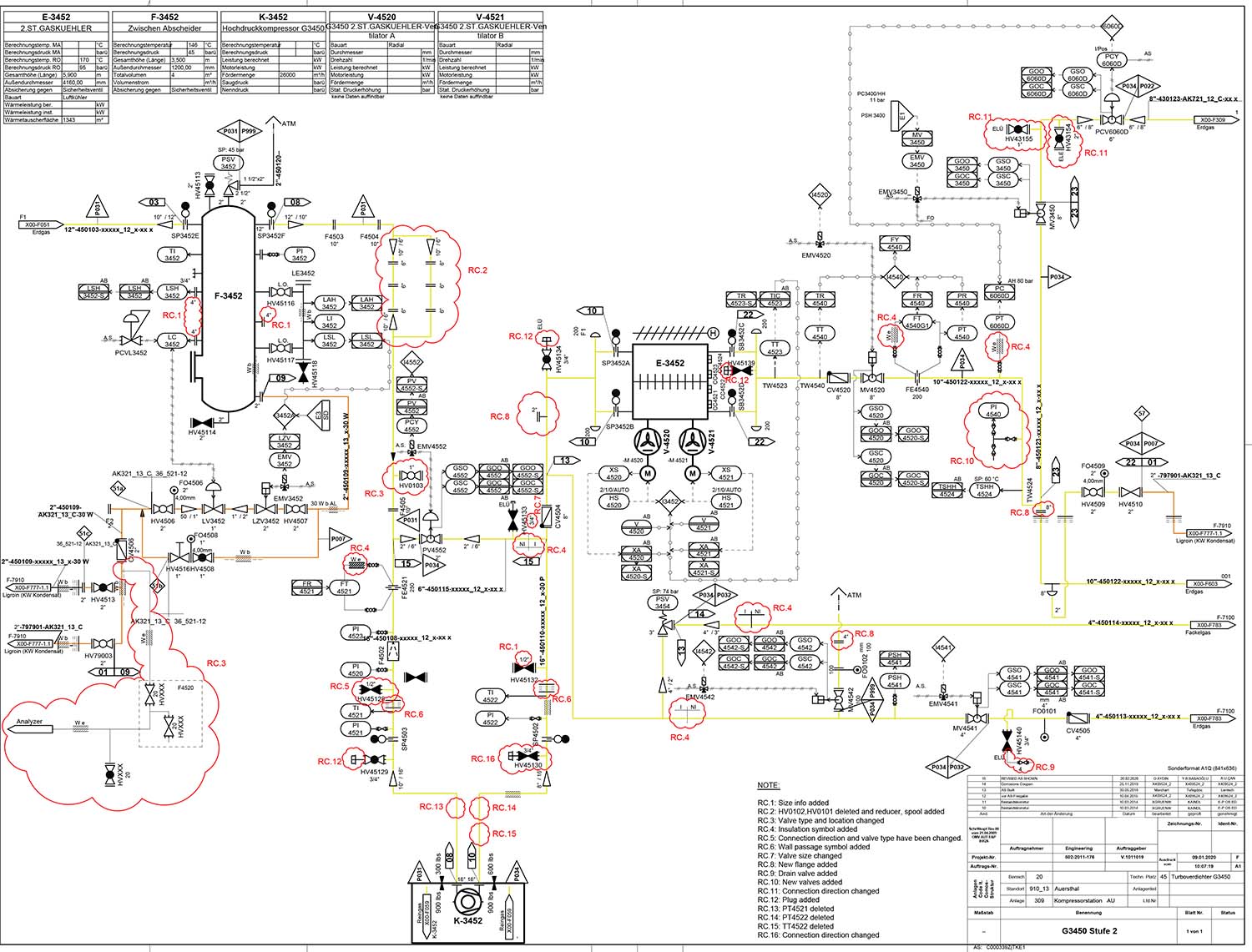

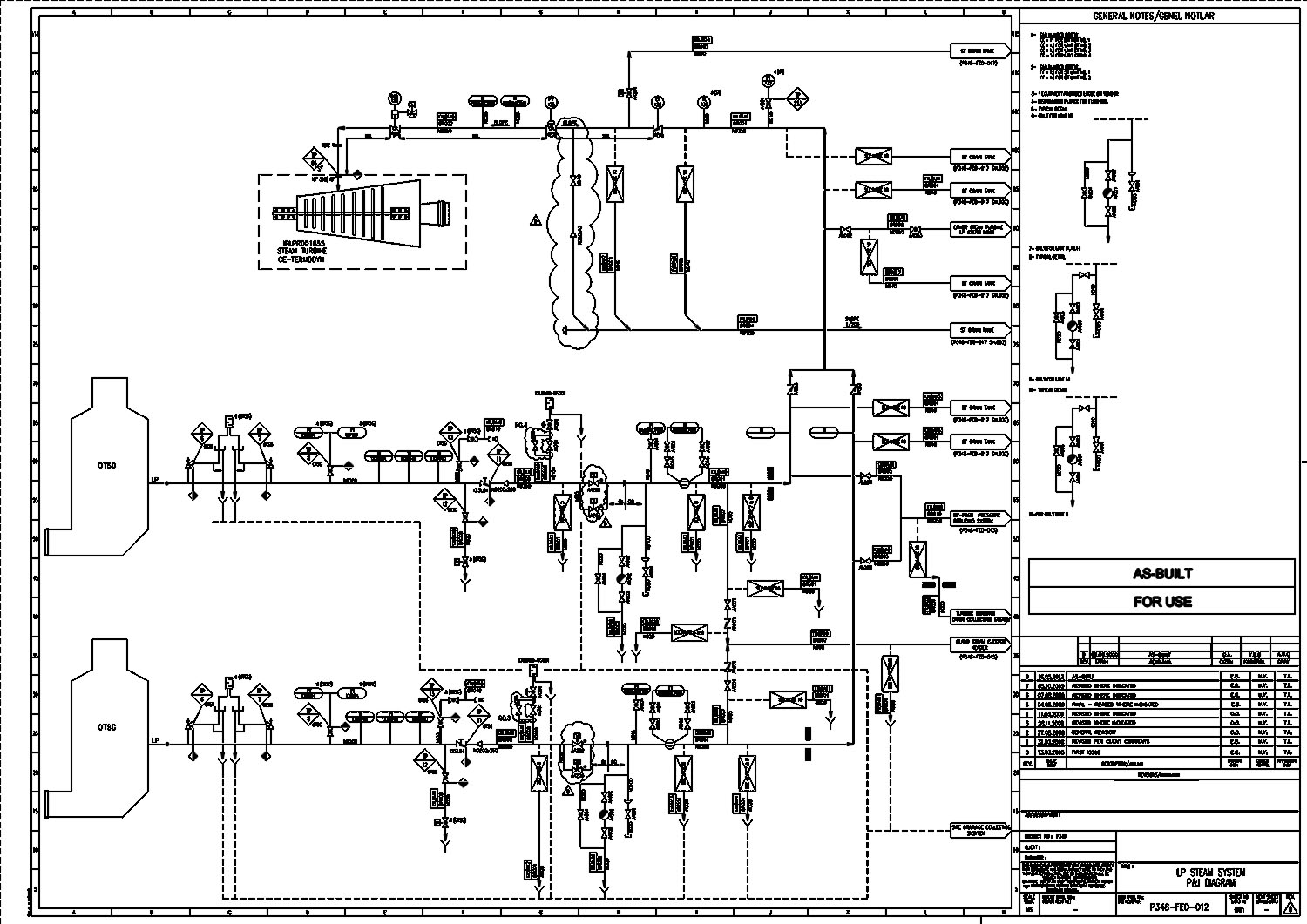

The Field Engineering team of mechanical and instrumentation engineers visits the site and marks up the existing P&IDs based on field conditions. If there is no available document to be verified in that area, the team will create new P&IDs by hand drawing for any systems or areas that have not previously been documented. Our team works closely with the customer to comb their existing files for equipment and instrument data that we then verify against equipment tags on site. This data will be brought to our offices and drafted.

GIZIL also offers Smart P&ID services, leveraging advanced software tools and technologies to digitize and optimize the management of Process and Instrumentation Diagrams. Smart P&IDs provide a dynamic and interconnected representation of a facility's processes, equipment, and instrumentation, enabling efficient information access and enhancing operational safety.

Through our Smart P&ID services, we transform traditional static diagrams into intelligent, data-driven models that integrate with other systems such as asset management, maintenance planning, and control systems. This integration enables real-time monitoring, streamlined workflows, and better decision-making throughout the facility's lifecycle. With accurate and up-to-date Smart P&IDs, organizations can optimize maintenance, reduce downtime, and improve overall operational efficiency.

Whether you require as-built verification for compliance and quality assurance or seek to unlock the potential of digitalized P&IDs for operational excellence, GIZIL is here to support you. We work closely with our clients to understand their unique requirements and provide customized services that drive productivity, enhance safety, and deliver tangible results.

Achieve precision and gain valuable insights with GIZIL's services for As-Built Verification and Smart P&IDs. Contact us today to learn more about how our expertise can help you optimize your projects, streamline operations, and ensure the long-term success of your facilities.

Get in Touch for As-Built Verification and Smart P IDs Services!