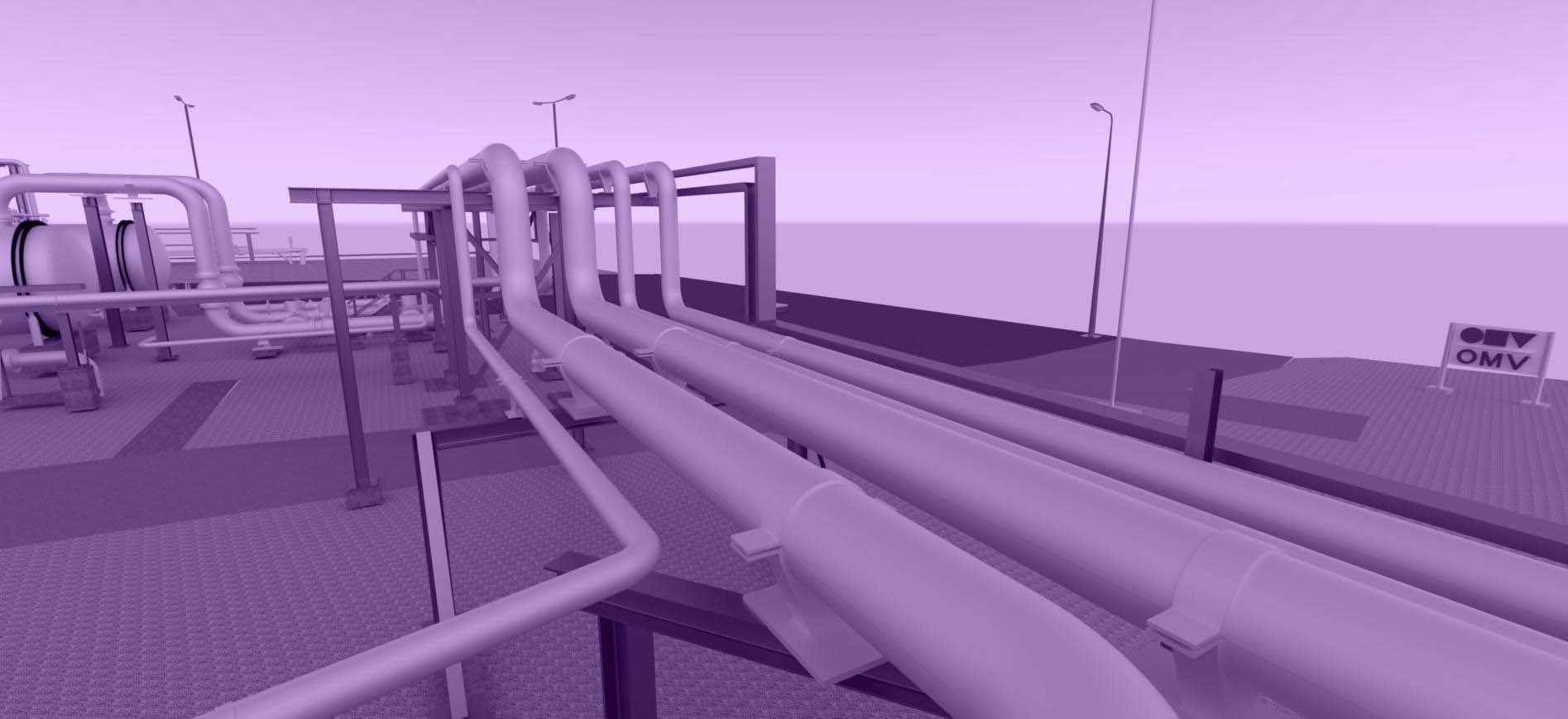

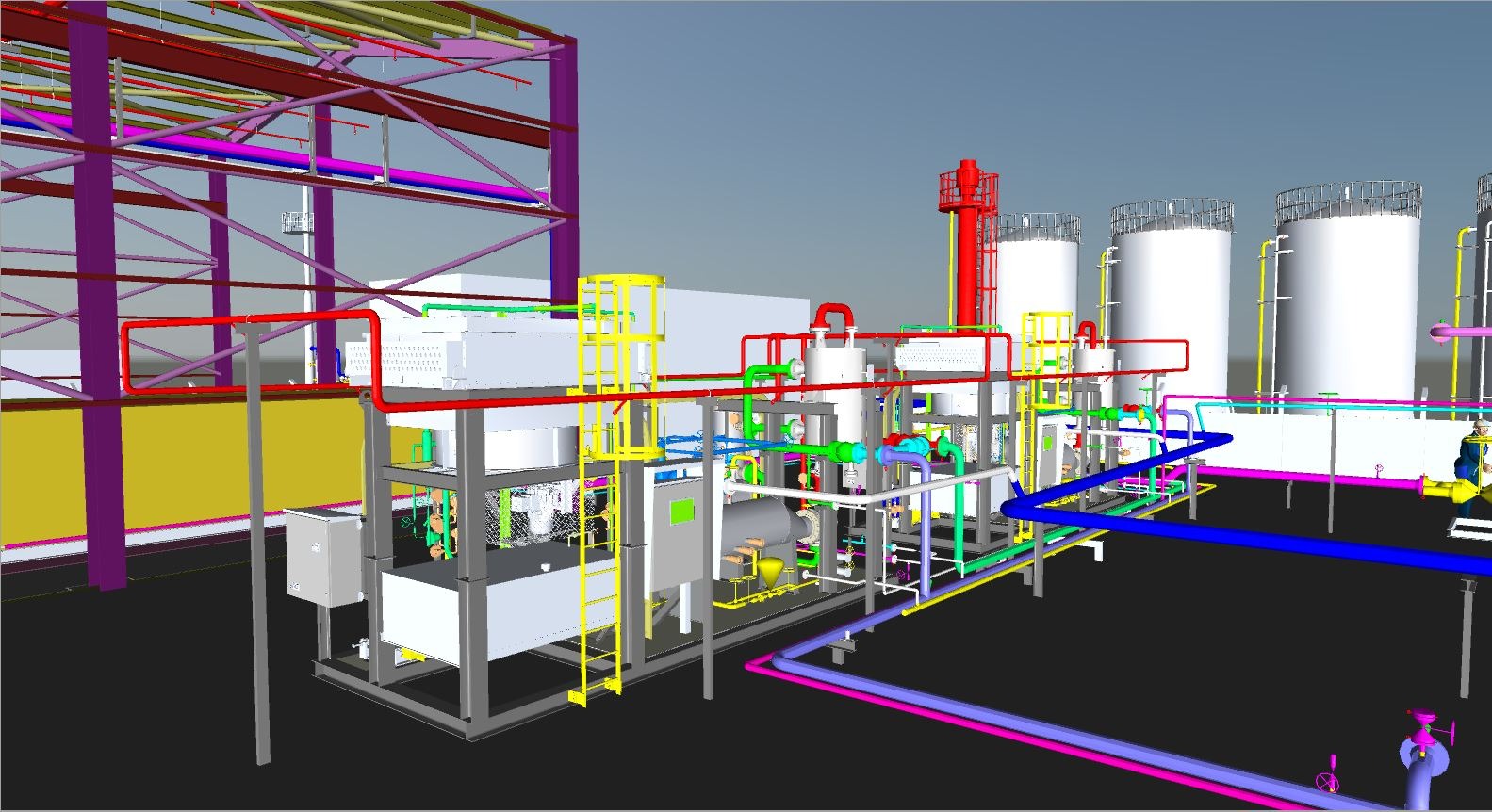

Piping & Plant Layout Engineering

The comprehensive design and engineering phase follows the FEED phase, in which every piece of equipment and pipe system component is completed and designated for procurement. During this phase, "Issued-For-Design (IFD)" pipe isometric drawings are created for study and comment by piping engineers and engineers from other disciplines whose opinion is needed. Plant layout is a crucial part of the design process for process plants and pipe networks. Plot plans are documents created during the design process of a facility. GIZIL's piping and plant layout engineering services include analyzing the piping materials and pipe stress. Our designers follow industry codes and standards, such as ASME, BS EN 13480, BS EN 14364, and Shell DEP.

Main Deliverables for Piping & Plant Layout Engineering:

- Process Piping Design

- Utility Piping Design

- Pipe Specifications

- Above and Under Ground Piping Systems

- Piping Routing and Modelling

- Isometrics

- Piping Stress Analysis

- Piping Support Calculations

- General Layout

- Key Plan

Piping Stress Analysis

The most significant task in Piping Design is Piping Stress Analysis. Once the pipes have been routed following the design criteria, they must be checked using piping stress analysis to guarantee that they will function properly during their design life. GIZIL has extensive project expertise in performing stress analysis services and piping flexibility studies for pipe systems. We do comprehensive pipe stress study, assessment, and validation of structural and operational integrity process piping system. Code and standards used for process piping stress analysis are ASME B31.3, ASME B31.1, API 610, API 676, API 617, ASME Sec VIII, ASME B 31.4/ASME B 31.8, and ISO 14692. We can perform pipe support selection, support standards development, support drawings, and surge analysis.