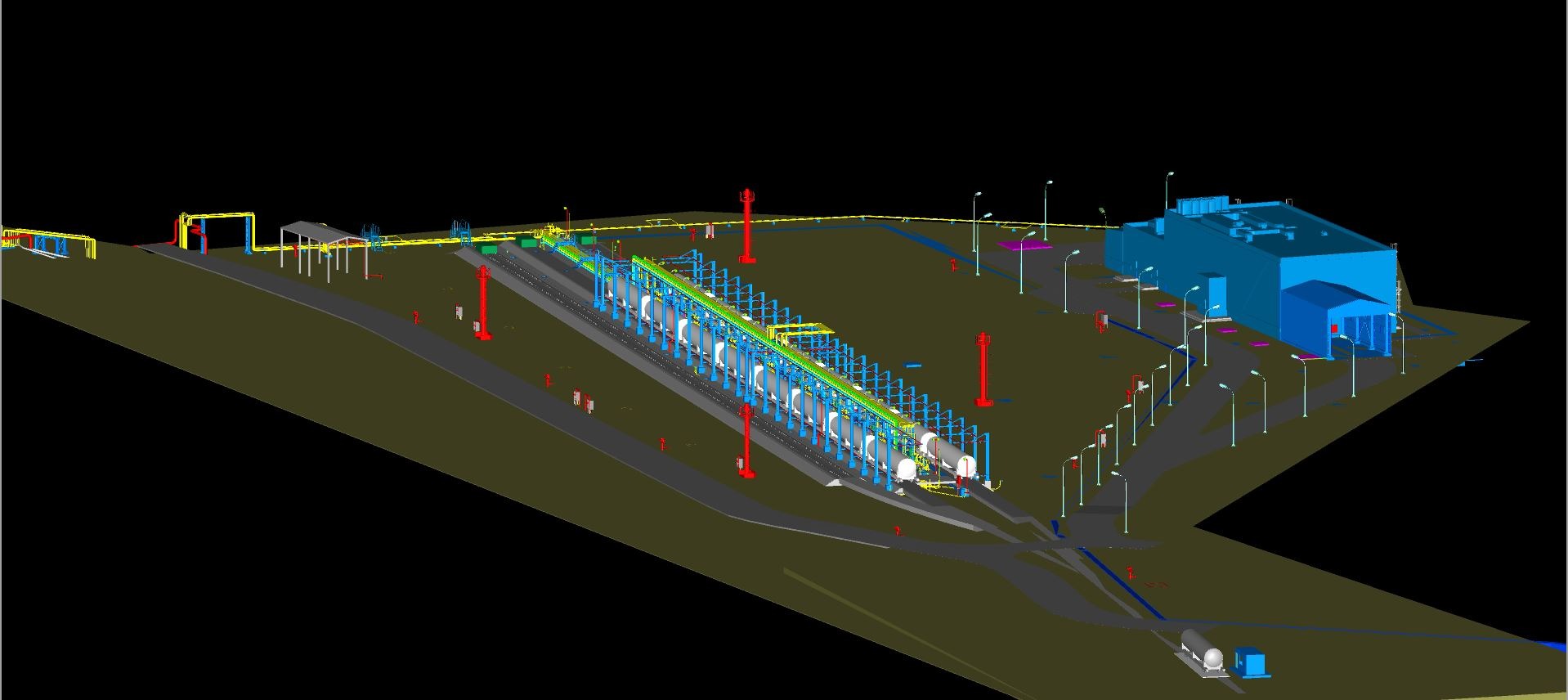

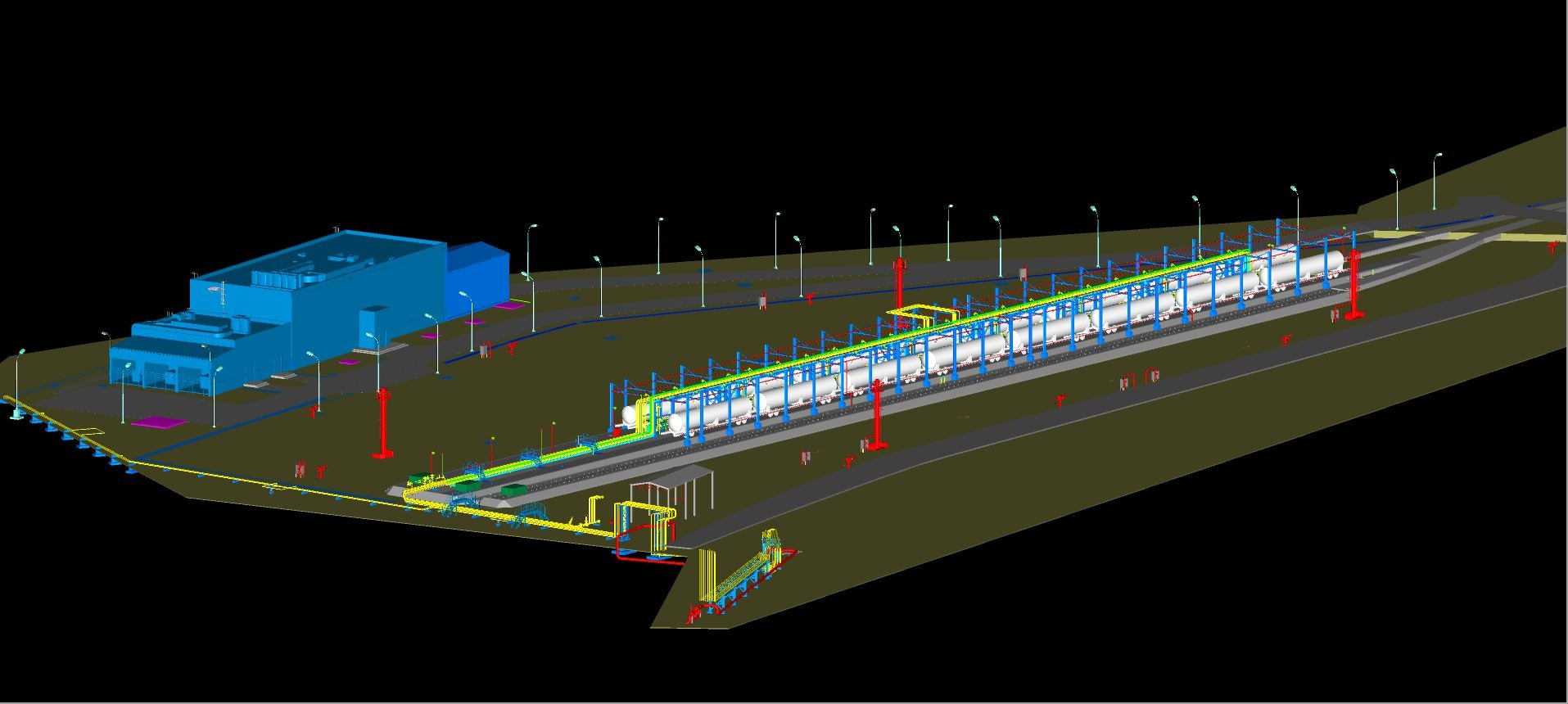

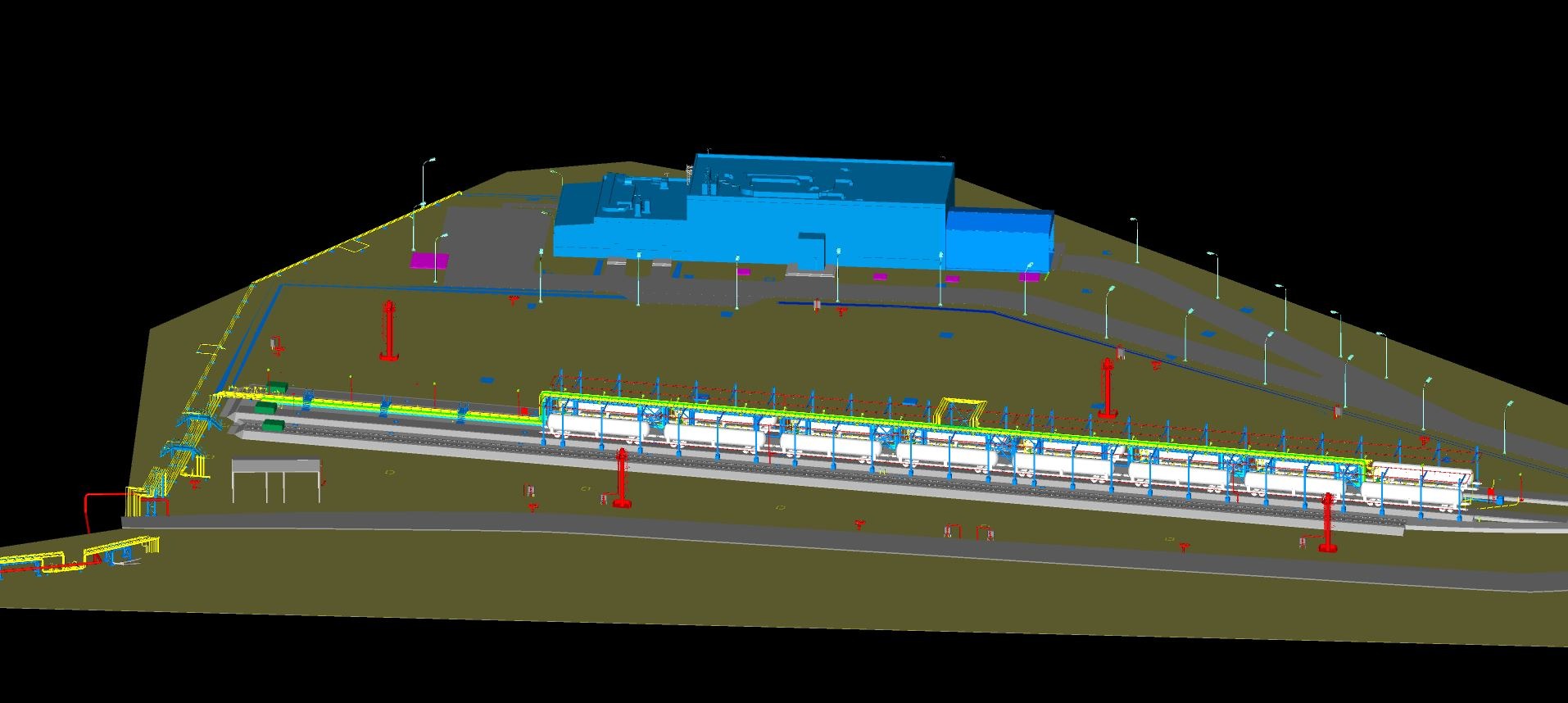

Basic and Detailed Engineering Studies of LPG Wagon Loading Unit Project

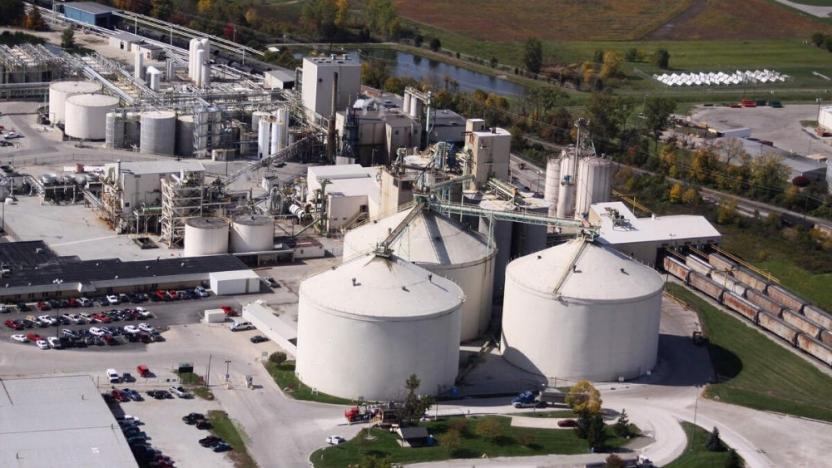

The customer, the largest industrial company in Turkey, has four refineries established in Kocaeli, İzmir, Kırıkkale, and Batman, with a total crude oil processing capacity of 28.1 million tons per year. As Europe’s 7th largest refining capacity, the company is one of the most complex refineries in the Mediterranean region, with an average Nelson complexity index of 9.5. After completing the Residuum Upgrade Project (RUP), the Izmit Refinery now has the highest complexity of any refinery in the region.

LPG transportation is planned between the Izmit and Kirikkale Refineries by rail. In this context, an LPG Wagon Filling Unit and a control building belonging to this unit is installed at the refinery. Filling is done in Izmit Refinery. It is planned to unload the wagons with the help of compressors at Kirikkale Refinery. The facility planned to be established 1500 ton/day capacity, to complete the filling process in 10 hours.

GIZIL is awarded as an engineering subcontractor to perform basic and detailed engineering deliverables of the project.

There are approximately 500 unique deliverables for all disciplines (process, safety, civil, piping, mechanical, electrical, instrumentation and control) in the context of this project.

Main scopes of the projects as follows:

- LPG liquid filling, vapor return and utility (service air, instrument air, steam, service water, potable water etc.) design

- Steam or electrical tracing design

- Checking the Material Specifications of the current relevant lines

- BEDD Review and its redesign, adding additional shut-off, control valve and control philosophy

- Calculation of the explosion effect and preparation of the solution proposal report

- Process control philosophy (IFR, IFD, IFC)

- Turning the Red-Mark drawings prepared after the application into an As-built project

- HAZID and HAZOP

- Design and project of the relevant protection instrumentation that may be required as HAZOP/SIL study outputs

- Preparation of commissioning & decommissioning procedures of LPG Wagon filling facility

- Hazardous Area Classification Drawings (IFD, IFC)

- Fire Network Layout Drawing

- PFD

- P&ID

- ESD philosophy

- Equipment Process Datasheets

- Single Line Diagram (General, Switchgear, MCC)

- Designing 3 new railways

- Materials of all equipment in the unit (TRV, PSV, PCV, Filling Arms, LPG Pumps, Skids, shut-off valves etc.)

- Preparation of purchasing specifications

- Design of all necessary support, pipe rack, road crossings and preparation of application projects

- New LPG tanks’ nozzle details

- Electrical calculations, drawings, and specifications (MCC, relay coordination, MV/AV cables, earthing, lighting, lightning, etc.)

- Civil and structure calculations, drawings, and specifications

- Instrumentations calculations, drawings, and specifications