Turkey's First and Only Dolphin Port Platform

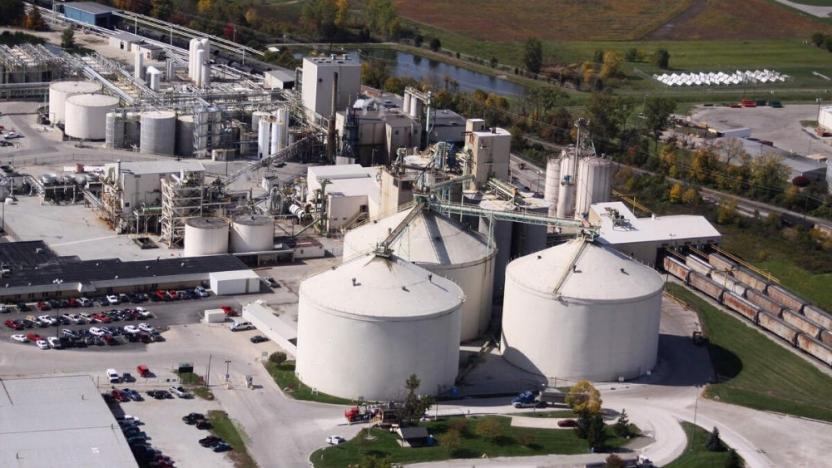

The customer is a well-established chemical supplier and distributor with a diverse product portfolio and a customer-focused approach. It has been providing integrated services to the textile, detergent, paper, food, and construction industries for over 30 years. Their expert team supplies bulk and packaged chemicals, stores them meticulously, and distributes them regularly. They contribute to the Turkish economy by conducting transit trade and exports to many countries around the world through their tank terminals located in Tekirdağ-Marmara Ereğlisi and Adana Yumurtalık Free Zone, both of which are classified as "Type A General Bonded Warehouses." In addition to chemical supply and distribution services, the company also provides logistics and storage solutions, as well as technical support and consultancy services.

The customer invested in a jetty project that was developed to facilitate the loading and unloading of chemical products by sea transportation. The project was completed in 2021 and involved the construction of a new jetty with a total length of 168 meters and a depth of 9 meters, along with supporting infrastructure such as pipelines, pumps, and tanks. The project was undertaken in order to increase the company's capacity to import and export chemicals by sea, as well as to improve its logistics and transportation capabilities.

The project was completed with the highest safety and environmental standards in mind. In particular, special measures were taken to prevent any potential environmental contamination, such as the installation of oil booms and oil skimmers, as well as the use of a state-of-the-art wastewater treatment plant.

This project is an important milestone for the customer, as it has enabled the company to expand its operations and strengthen its position as a leading chemical supplier and distributor in Turkey and the surrounding regions. By investing in the necessary infrastructure and resources, the company has demonstrated its commitment to providing high-quality services to its customers, while also ensuring the safety of its employees and the environment.

GIZIL was awarded as an engineering contractor to perform basic and detailed engineering deliverables of the project. In the project the basic engineering activities likely involved the development of the initial concept and feasibility studies for the new jetty. This included defining the basic layout and design requirements, as well as assessing the economic and technical viability of the project.

Detailed engineering activities included the development of detailed drawings and specifications for the jetty and its supporting infrastructure, such as pipelines and pumps. This included calculations for load capacities, structural design, and other technical requirements. The detailed engineering activities consisted of the development of safety and environmental management plans, as well as risk assessments and mitigation strategies. This ensured that the project was designed and constructed in accordance with the highest safety and environmental standards.

Overall, the project involved a range of engineering activities, from the initial concept and feasibility studies through to the detailed design and documentation of the new jetty and its supporting infrastructure. By GIZIL’s engineering resources and expertise, the customer was able to successfully complete the project and expand its operations in the chemical industry.