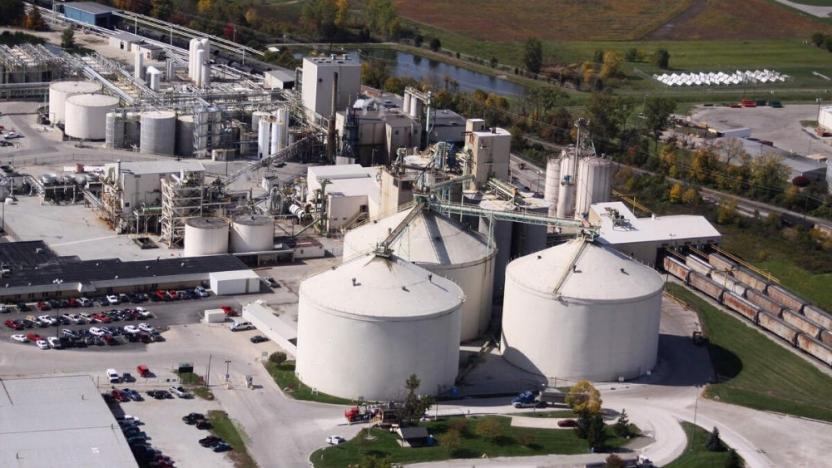

Revamping and Upgrading LNG Terminal: Enhancing Send Out Capacity through Electrical & Instrumentation Innovations

Customer is a state-owned Turkish energy company responsible for the transportation and trade of natural gas throughout Turkiye. Established in 1974, it plays a critical role in managing and implementing major energy projects in Turkiye. The LNG Terminal, one of the vital facilities, is a strategic import terminal providing natural gas supply to Turkiye's extensive natural gas pipeline network. The terminal, equipped with the latest technology, aims to ensure secure and reliable natural gas supplies to meet the country's growing energy needs.

This project directly contributes to customer’s strategic goals by increasing the send out capacity of this terminal. It enhances the terminal's efficiency, enabling customer to maintain a reliable supply chain and meet the growing demand for LNG in Turkiye more effectively.

This comprehensive project was aimed at increasing the send out capacity of the LNG Terminal. The scope of the project included the Electrical and Instrumentation works which were carried out with a keen focus on safety, quality, and timely delivery. The work involved product supply, dismantling, installation, testing, and commissioning for a variety of systems.

The specific components of the project scope included:

- 6.3kV System: Revamping the existing system and enhancing the capacity of the medium voltage system.

- 0.4kV System: Upgrading the low voltage system to improve efficiency and reliability.

- Metering Station: Delivering a fully equipped metering station, along with its integration into the existing facility.

- Automation System Including ESD Integration: Design, supply, and installation of a comprehensive automation system with integrated Emergency Shutdown (ESD) system, improving safety and process control.

- Instrumentation: Supply and installation of a variety of instrumentation devices, enhancing the plant's measurement and control capabilities.

- Fire & Gas Detection System: Installation of a robust Fire and Gas detection system, ensuring improved safety standards for the facility.

- Medium Voltage Cables: Supply and installation of medium voltage cables, as part of the upgrade of the 6.3kV system.

- Low Voltage Power Cables: Supply and installation of low voltage power cables, supporting the upgrade of the 0.4kV system.

Our team successfully completed the project on schedule and within the agreed-upon budget, ensuring a high standard of quality and safety throughout all aspects of the project.

- Successful Integration: Successfully integrated the new systems with the existing facility with minimal disruption to ongoing operations.

- Enhanced Capacity: The upgrade and revamping of the 6.3kV and 0.4kV systems resulted in increased send out capacity of the LNG plant.

- Improved Safety: The installation of an advanced fire and gas detection system and an ESD integrated automation system significantly improved the safety profile of the plant.

- Supply Chain Efficiency: Managed an effective supply chain for product delivery, ensuring high-quality materials and equipment were used.

The project has contributed to the client’s goal of enhancing the LNG plant’s capacity and operational efficiency, thereby meeting increased demand and further cementing their position as a leading provider in the LNG sector. In the course of the project, we gleaned valuable insights and lessons that will serve to improve future projects. We remain committed to a process of continual learning and improvement, ensuring we offer the best possible service to all our clients.