Design and Build of Electrical Heat Tracing System of a Bitumen Storage Terminal

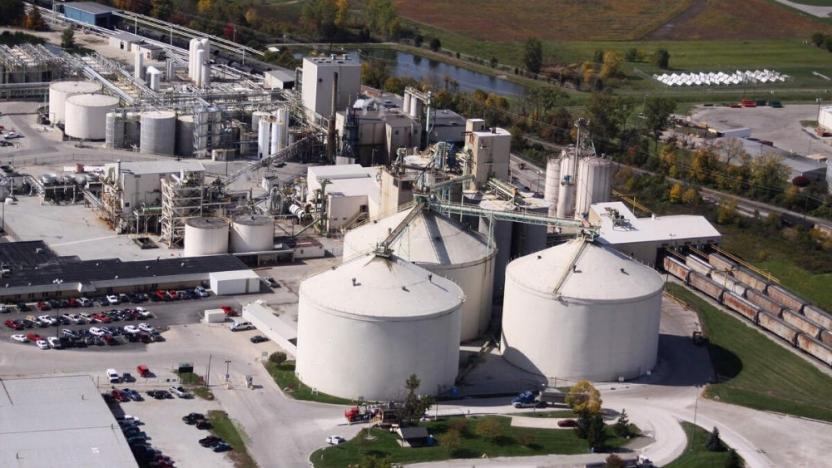

The customer is a leading tank farm company of the country and has a major plant in Dortyol, Hatay. The progressive sophistication of oil products and increased volatility in the global oil markets requires flexible value added and diverse logistics services in global markets. Within this context, our customer with its differentiated service capacity will become a worldwide logistics center in the growing Mediterranean and nearby regional hub.

A large bitumen storage facility was planned and implemented at the beginning of 2022. Within the scope of project, 2 tanks will be renovated, 6 new tanks established to the next of those tanks, jetty and land loading-discharge facilities to store bitumen. After the completion of installation activities, the plant will be the largest bitumen storage facility in the country.

Our scope of supply is a turnkey heat management solution (E&D, installation, and start-up). Mainly, the application is heating up the bitumen in transfer lines to the targeted temperature in a limited duration and maintain its temperature.

Finite Element Analysis (Computational Fluid Dynamics) method has been used with real life data to illustrate the behavior of bitumen during the heat up process. Using such an approach, the customer is assured that the system to be installed will meet the process requirements.