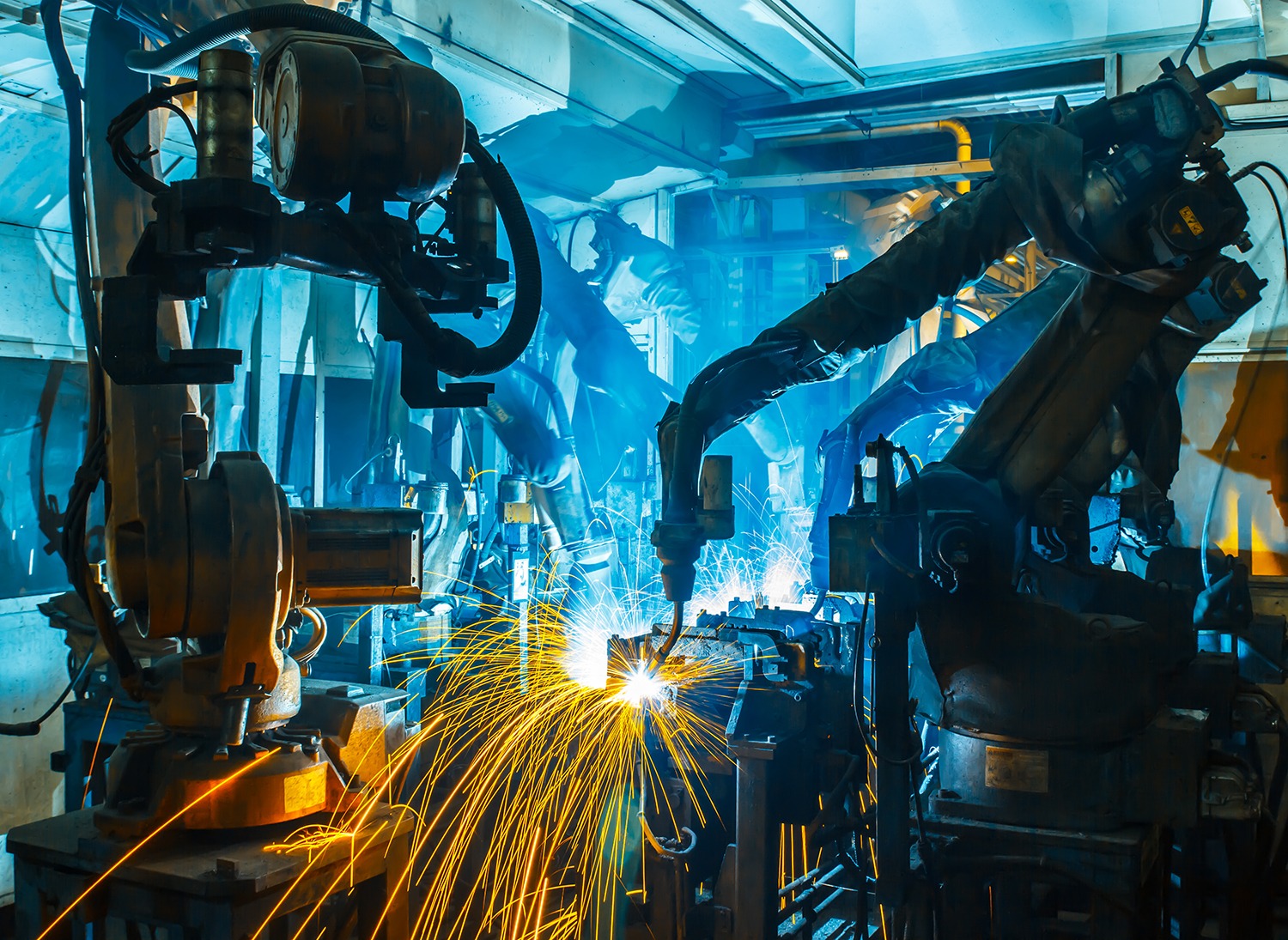

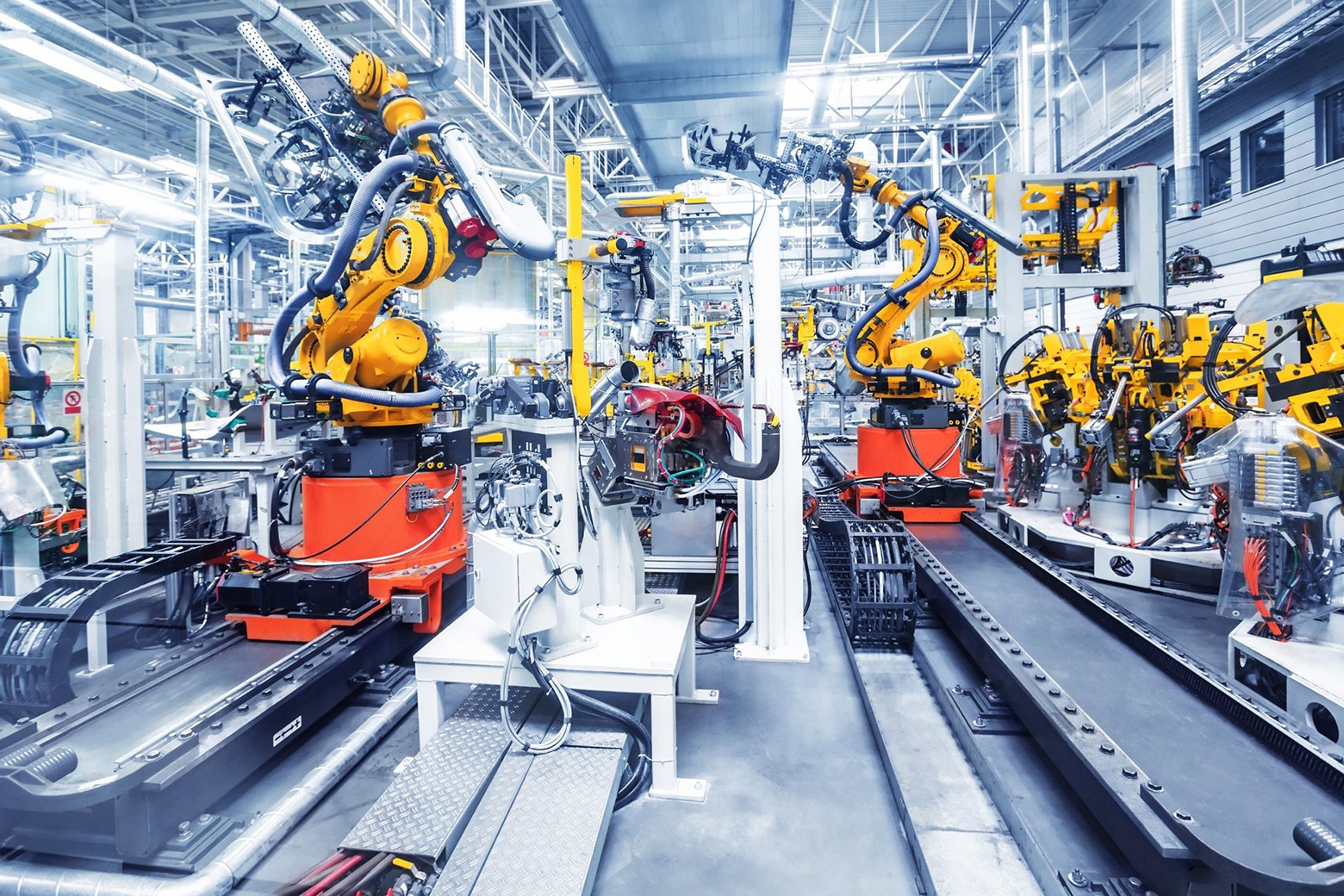

Revolutionizing Manufacturing, Redefining Excellence: Your Gateway to Digital Twin Solutions for Industry 4.0

The manufacturing industry is quickly rebuilding despite substantial labor and supply chain issues. Manufacturers must negotiate heightened risks while pursuing sustainable objectives to retain this momentum.

Our digital solution provides you with immersive access to necessary plant knowledge, such as exact measurements of the structure and dimensions of the equipment.

Manufacturers who want to seize growth while preserving long-term profitability should embrace digital capabilities from corporate processes to the production floor. For many firms, smart factories, including greenfield and brownfield investments, are considered one of the keys to boosting competitiveness. More firms are making headway and experiencing returns from more connected, dependable, efficient, and predictive plant operations. With the appropriate combination of vision and execution, emerging and changing use cases may continue to grow from isolated in-house technology initiatives to whole production lines or factories.

Our digital solution provides you with immersive access to necessary plant knowledge, such as exact measurements of the structure and dimensions of the equipment. It allows you to evaluate present circumstances readily, but it can also enhance plant management and design. You can remove hand-drawn sketches and shorten the time it takes to deliver 2D documents by using our 3D scanning technology. Our technology allows you to establish equipment inventory on the go by labeling equipment with digital tags to capture repairs, maintenance, or training information. It's simple to share with your maintenance staff. Using a digital tag tool to capture repairs, maintenance, and training information, various media types may be put precisely where viewers will discover relevant content.

Another advantage is that you may boost cooperation with teams from all around the world. Visualization will increase communication when discussing existing projects on site, but it will also improve efficiency in the inspection and decision-making process. In a virtual environment, new workers may undergo safety training and inductions. A 3D tour increases staff training. Advantages include interactive learning, site-specific training, installations, and 24/7 access.

Explore our services for Manufacturers