Virtual Operator Training

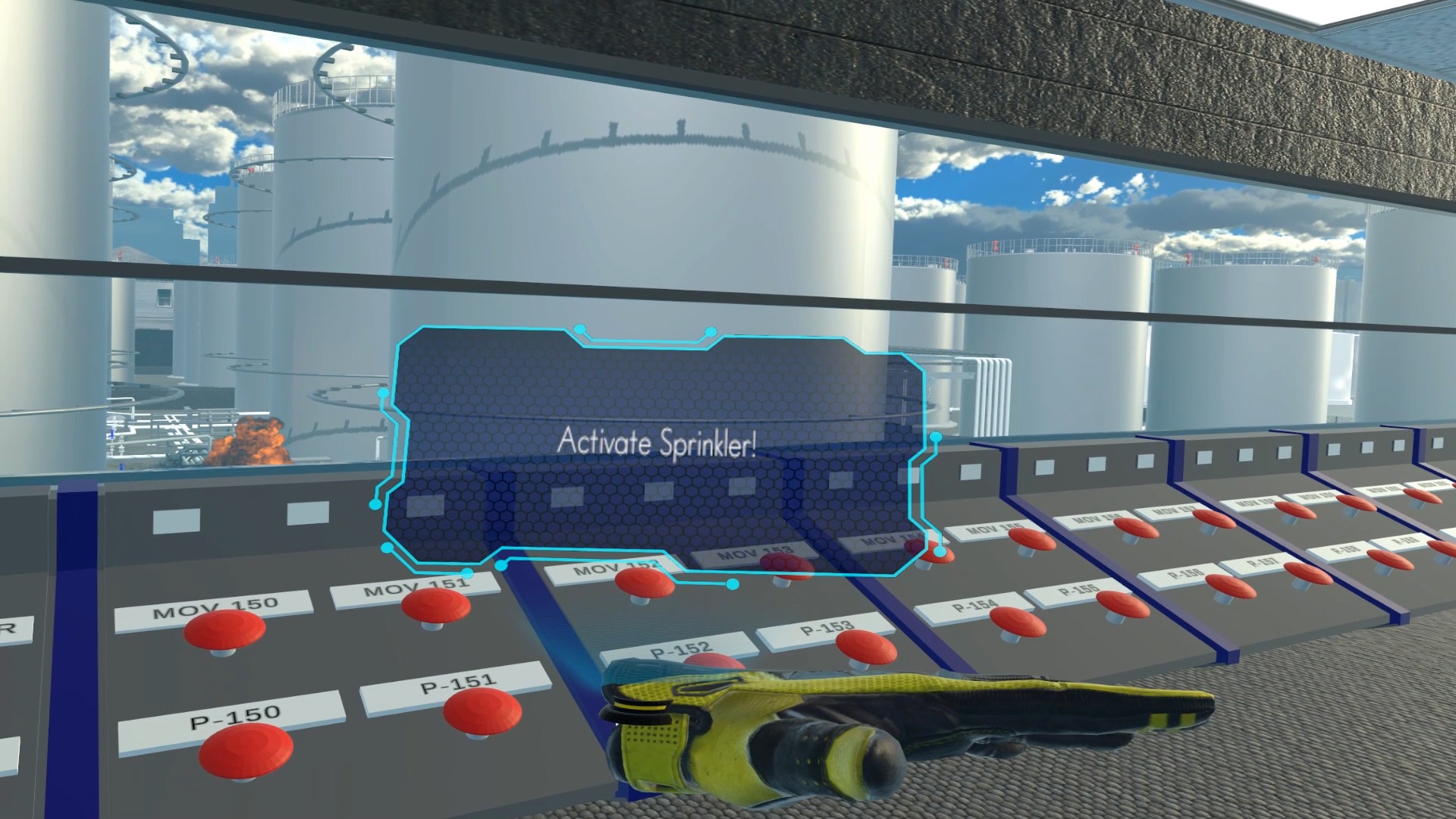

According to research, people learn best via experience. The memory of training materials and courses is boosted by establishing safe experiences in the security of a controlled, virtual environment. To create unforgettable experiences, virtual and augmented reality provides a feeling of scale, height, and realism. The training starts with a description of the controls. Personal protection equipment, including gloves, a hard helmet, and safety glasses, are essential for trainees.

To develop a virtual training environment, a digital twin, or digital counterpart, of your existing production assets is used. GIZIL has full capabilities to capture plant data, 3d modeling, and gamification. There is no need to shut down a physical machine or wait for a new one to arrive to educate operators. Instead, you may digitally reconstruct the mechanism in great detail. You may also use physics to simulate how the machine moves and interacts with people and other machines.

Operators can then use a PC screen or a VR headset to access the digital twin and learn in a secure, immersive training environment. When operators are placed inside a dynamic digital twin model, they no longer require a real machine to train, nor do they need to be in the same area as the machine. Consider the convenience of being able to train on a machine model from anywhere globally.

Operators can then use a PC screen or a VR headset to access the digital twin and learn in a secure, immersive training environment. When operators are placed inside a dynamic digital twin model, they no longer require a real machine to train, nor do they need to be in the same area as the machine. Consider the convenience of being able to train on a machine model from anywhere globally.