FEL is a project execution model that uses a phased approach to let stakeholders handle risks and commit extra resources at well-defined approved milestones throughout the project life cycle. Front-end loading engineering should be a flexible procedure that benefits project engineers on projects of any size. A correctly implemented FEL program results in more successful projects with improved cost and schedule performance, better risk management, and fewer scope changes.

FEL-1 Feasibility Study: Define Project Ideas Alternatives

Deliverables for FEL-1 Typical Content:

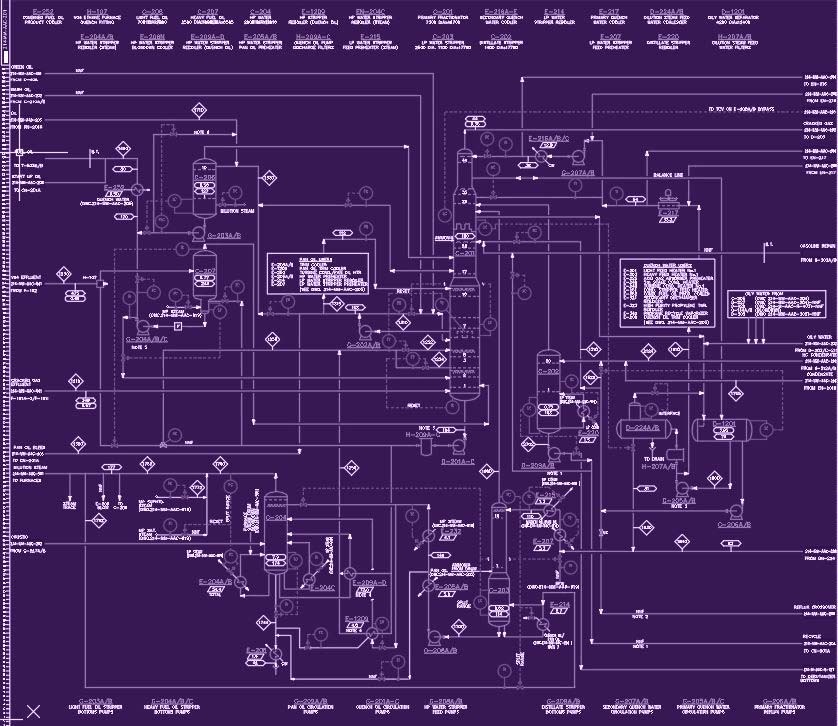

- Process Flow Diagram

- Key Plan/Site Plan

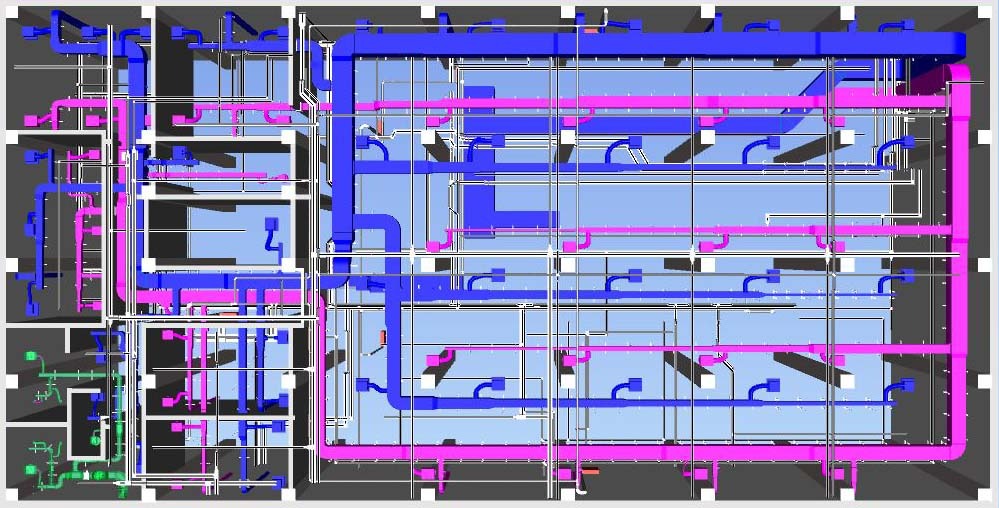

- General Arrangement(s)

- Preliminary Design Calculations

- Major Equipment List

- FEL 1 Report

- Cost Estimate Accuracy +/-30 %

FEL-2 Content Select: Evaluate Alternatives

Deliverables for FEL-2 Typical Content:

- Process Flow Diagram

- Key Plan/Site Plan

- General Arrangement(s)

- Preliminary Design Calculations

- Major Equipment List

- Preliminary Soil Investigation Report (as required)

- Equipment Quotations

- Preliminary Specifications

- FEL 2 Report

- Cost Estimate Accuracy + 25/-10%

FEL-3 FEED: Define the plant to be built

Deliverables for FEL-3 Typical Content:

- Process Flow Diagram

- Preliminary P & ID Drawing

- Key Plan/Site Plan

- General Arrangement(s)

- Preliminary Electrical Schematics

- Preliminary Cable Schedule

- Preliminary Piping Line List

- Preliminary Vendor Information/Drawings

- Preliminary Design Calculations

- Equipment List

- Preliminary Instrument List

- Process Hazards Review

- Preliminary Soil Investigation Report (as required)

- Equipment Quotations

- Preliminary Specifications

- FEL 3 Report

- Cost Estimate Accuracy +15/-10%