3D Inspection and Dimensional Control Surveys

GIZIL's Dimensional Control and Monitoring services, which employ tried-and-true engineering survey procedures and cutting-edge survey technology, may add significant value to any project. Dimensional Control collects exact as-built 3D data on new or existing mechanical, structural, and civil engineering projects using proven engineering survey procedures and high technology survey equipment. This carefully obtained spatial data, like laser scanning, is employed throughout project planning and execution to eliminate uncertainty linked to interface integration and measurement abnormalities.

Dimensional control applications

- 3D inspection of storage tanks

- Deformation analysis for wind turbines and solar panels

- Clash/interference assessments for mechanical component replacement or installation

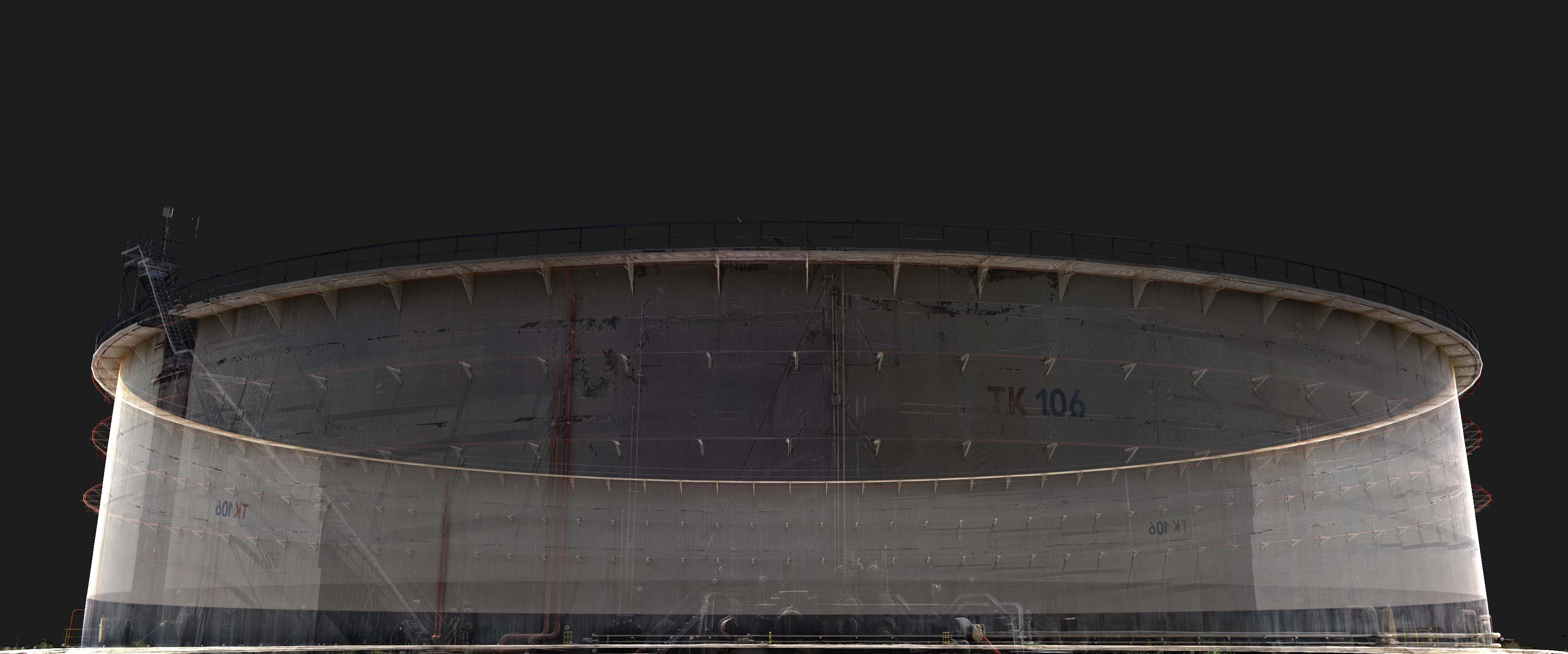

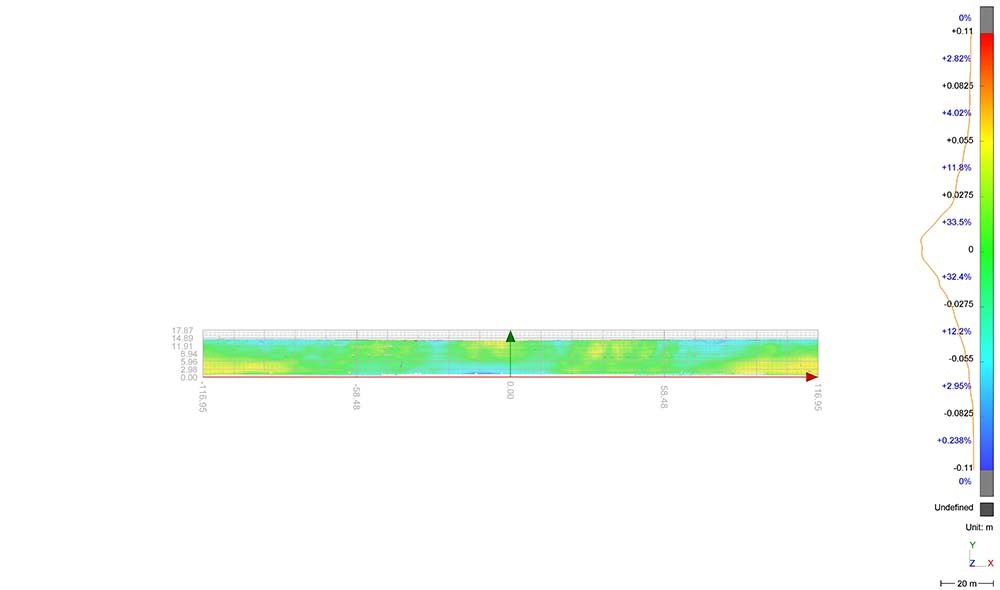

Storage Tank 3D Inspection

A storage tank inspection may be a challenging operation, but thanks to 3D scanning technology, we can now address your concerns. High-precision laser scanning methods are used to get three-dimensional measurements in various applications, including tank settlements, volume calculation, and deformation analysis.

Solar Farm Inspection with Drones and Thermal Mapping

Solar power plants also have some challenges like mismatch losses caused by the interconnection of solar cells or modules that do not have identical properties, reduced current losses caused by soiling, shading, degradation, and series and shunt losses. GIZIL addresses these challenges thanks to high-tech data capturing solutions. According to the flight plan, we carry out flights with competent unmanned aerial vehicles (UAV), equipped with thermal and RGB cameras, in the area where solar panels are located. UAV operators can visually check solar panels on-site before post-processing. All collected data are stored for the processing stage. All captured thermal and RGB images are aligned and merged by Photogrammetry software to generate orthomosaic. Analyze team examines captured RGB and thermal imagery to detect anomalies. Following processing and analysis, data is delivered to the client in a user-friendly, actionable format.

Wind Turbine Blade Inspection

Most common wind turbine blade failures are lightning strikes, blade design, manufacturing and installation issues, improper handling during transportation, construction, improper assembly, axial stress, icing, and blade edge erosion. We can supply the most acceptable option for determining any fault with our skilled UAV Pilots and precision drones. Depending on the mission inspection, drones can be fitted with an RGB or infrared camera when inspecting wind turbines. This method detects structural flaws in wind turbines and their rotor blades, saving time and money while boosting safety.